Extraction Equipment: Essential Tools for Efficient Heat Exchanger Services

Heat exchangers are vital in industries like petrochemical, agriculture, and energy, enabling efficient thermal management by transferring heat...

3 min read

ParFab Companies : July 25, 2023 2:36:17 PM CDT

ParFab’s expert specialty Alky and Hazardous Unit teams work efficiently, with uncompromised safety, quality and project management skills to make your next shutdown, chemical neutralization, mechanical turnarounds and start-up project a success.

Here's how we do it:

Our highly qualified and proven management, supervision, craftsmen, and support specialist teams have unmatched industry experience in:

Learn more about phases of a turnaround project.

HF Alky Unit Demo Project for Phillips 66

HF Alky Unit Demo Project for Phillips 66ParFab named "Crew of the Week" by Phillips 66 for work on the DW HF Alky demolition.

ParFab's highly trained management and supervision has over 200 years of combined HF (hydrofluoric acid) and SF (sulfuric acid) alky experience. All of our craftsmen and support staff are highly qualified & experienced on HF Acid Alky and Hazardous Unit projects.

| Alky Experience | Title | Team Size Supervised |

|---|---|---|

45 years |

Alky Specialist |

- |

35 years |

Sr Project Mgr |

800 |

17 yrs |

Sr Project Mgr |

500 |

30 yrs |

Project Mgr |

475 |

17 yrs |

Project Supt |

250 |

16 yrs |

Project Supt |

250 |

15 yrs |

Project Suptr |

350 |

12 yrs |

Project Suptr |

200 |

12 yrs |

Equipment Supt |

150 |

22 yrs |

Project Supt |

450 |

Mobile facilities play a crucial role in the maintenance and shutdowns of alkylation units. When these units require maintenance or shutdown planning, having a mobile facility on-site is essential for safe and efficient neutralization of the process HF.

ParFab's state-of-the-art mobile decontamination facilities, including decontamination trailers and 8 PSI blast resistant buildings, provide the necessary infrastructure for effective decontamination. These facilities are equipped with heavy-duty washers and dryers, neutralization vats, foot baths, and safety showers to ensure thorough decontamination of personnel and equipment.

All mobile decontamination facilities include:

During an industrial alkylation shutdown, it is crucial to have the appropriate personal protective equipment (PPE) in place to ensure the safety of workers and the efficient completion of the shutdown. Due to its importance during such a project, ParFab offers specialty PPE such as acid suits, breathing air suits, and specialty chemical gloves to provide maximum protection for workers.

These PPE items are designed to withstand the hazardous conditions associated with alkylation units, ensuring that workers are shielded from harmful chemicals and substances.

Additionally, ParFab offers extensive HF Alky training programs to equip field employees with the necessary knowledge and skills to work safely in these environments. With a strong emphasis on safety and environmental protection, ParFab maintains a goal zero culture and proactively addresses potential risks. By prioritizing the use of appropriate PPE and providing comprehensive training, ParFab ensures that workers are well-prepared to handle alkylation shutdowns in a safe and efficient manner.

Below are the extensive HF Alky Training Programs that ParFab offers:

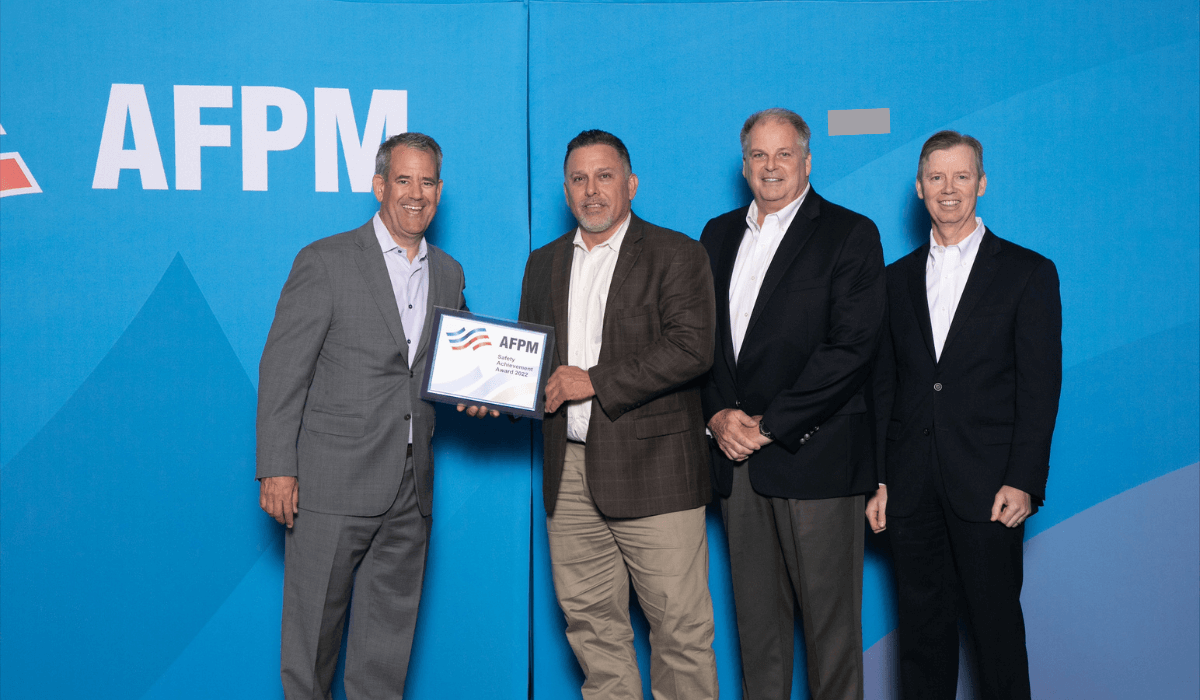

AFPM Contractor Safety Award

AFPM Contractor Safety AwardParFab is proud to announce that it recently received the Contractor Safety Achievement Award at the American Fuel & Petrochemical Manufacturers (AFPM) Annual Safety Awards.

Alkylation shutdowns pose significant hazards, making it crucial to prioritize safety during emergency turnarounds and shutdown projects. ParFab understands the importance of maintaining a safe working environment and has implemented various measures to ensure the well-being of our team.

Our expert Alky and Hazardous Unit teams emphasize safety, quality, and project management skills to guarantee successful shutdowns, chemical neutralization, turnarounds, and start-up projects. By prioritizing safety and environmental protection in the industrial space, ParFab maintains a goal zero culture, going above and beyond to stress safety during alkylation shutdowns, making us a reliable and trusted partner in the industry.

ParFab safety and environmental standards include:

ParFab's commitment to quality is evident through our certifications and KPI tracking, ensuring leak-free start-ups and minimal weld repair rates. By utilizing mobile alkylation units, we ensure that maintenance and shutdowns are conducted efficiently, safely, and to the highest standards of quality.

Below is our quality assurance to our partners and clients:

ParFab has not taken the Alkylation and Hazardous Unit business lightly but has gone to great lengths to assure our stake holders, employees, and our clients that we have the best-of-the-best; polices, procedures, equipment, management, supervision, craftsmen, and support personnel to perform all projects safely and efficiently. Combining our 200+ years of experience, we have produced a detailed HF Alky manual with over 1,000 pages of policies, procedures, training, and lessons-learned recommendations.

Heat exchangers are vital in industries like petrochemical, agriculture, and energy, enabling efficient thermal management by transferring heat...

We are excited to announce the sale of our Industries Heater Manufacturing Division to Heater Specialist LLC (HSI), signifying a strategic pivot in...

Welding is a vital part of metal fabrication, used to join two or more pieces of metal together. There are several types of welding processes, each...